CEMBOX is a level four Digital Twin platform according to AUTODESK classification. This technology is adaptable across various devices, offers near real-time (NRT) monitoring data and provides an interactive, intuitive, and multilingual 3D representation. It enables our users to access the most accurate and detailed project information, enhancing decision-making and operational efficiency.

CEMOBOX is a digital twin solution for the advanced management of buildings and infrastructures.

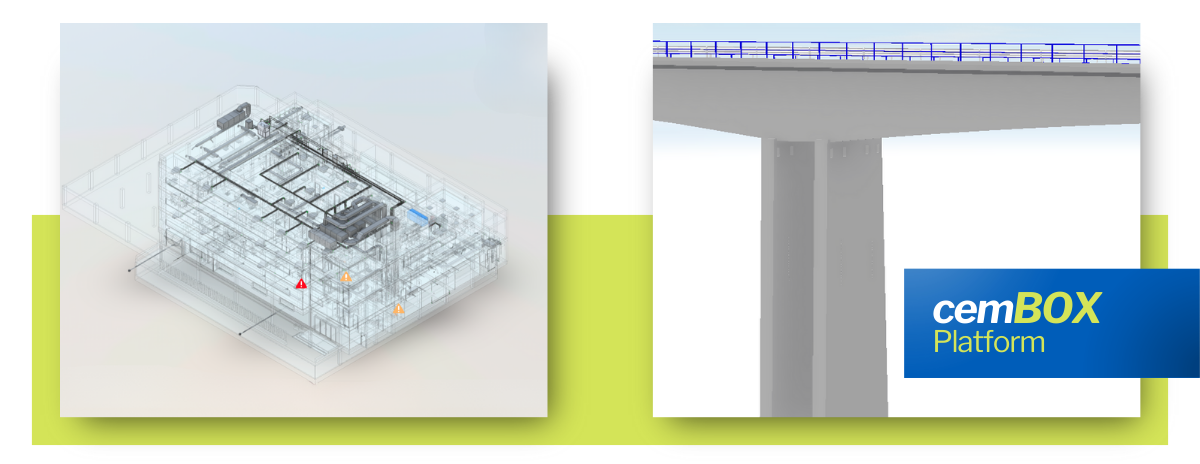

CEMBOX Building

CEMBOX Building is a virtual replica of a built asset (building) including:

- Static data (BIM models)

- Dynamic data (real time monitoring data)

- Indicators (data procesing)

- Scenarios simulation (energy performance models)

Who are the stakeholders?

It is aimed at facility managers, building users and owners and energy experts seeking to maximise performance and minimise operating costs throughout the building lifecycle.

CEMBOX Building Functionalities

- Real time and historical data on energy & indoor environmental quality

- Remote inspection and data visualization

- Analisis & Control on energy & indoor environmental quality

- Energy saving potential based on a reference building

- Dynamic energy score

- Accurate evaluation of energy conservation measures

- Energy efficiency alarms

CEMBOX Building Advantages

- Energy and comfort problems & enhancements quickly identified.

- Highly accurated energy models.

- User engagement and awareness towards energy efficiency.

- Comprehensive information for Facility Managers to keep high energy efficient buildings performance.

- Reduce risk of investment in energy refurbishing.

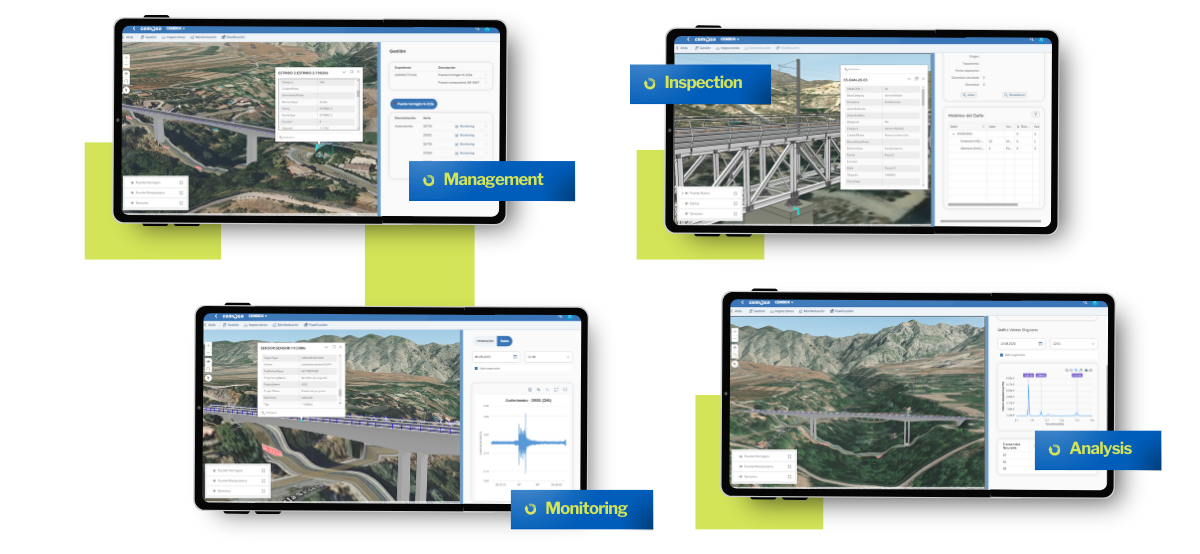

CEMBOX Infrastructure

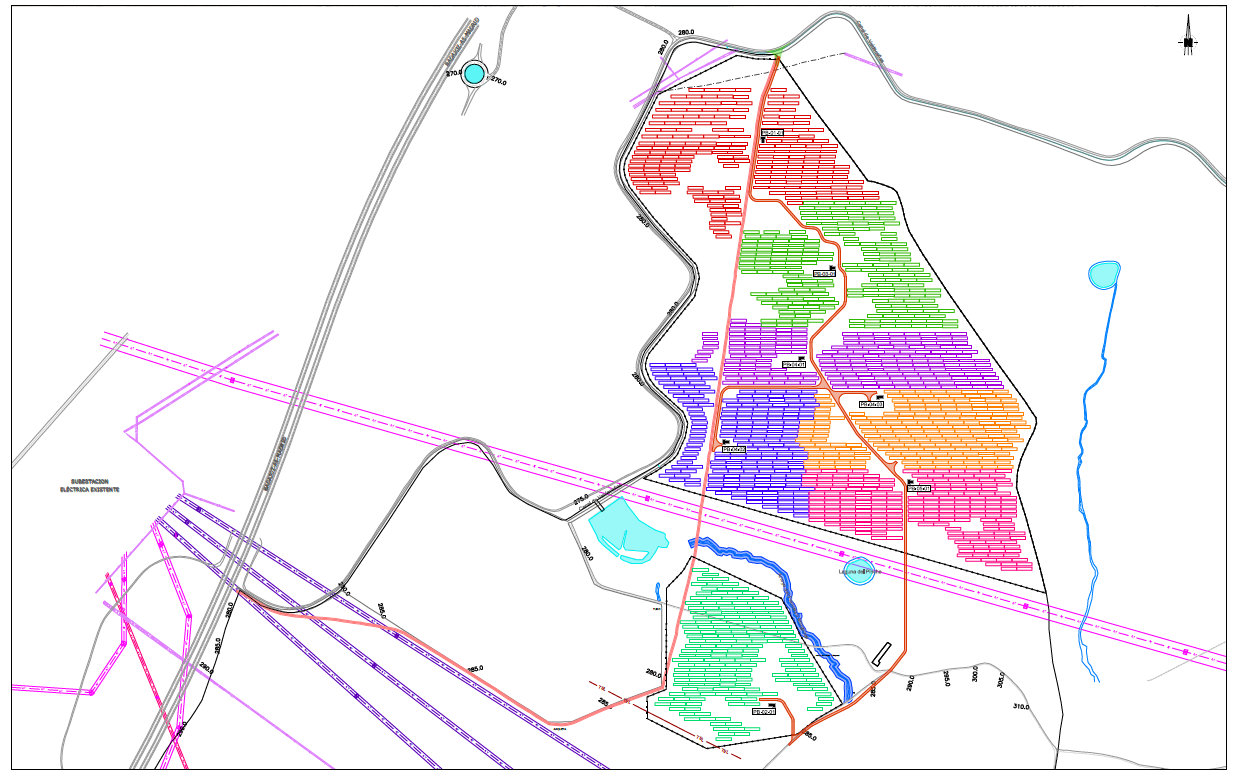

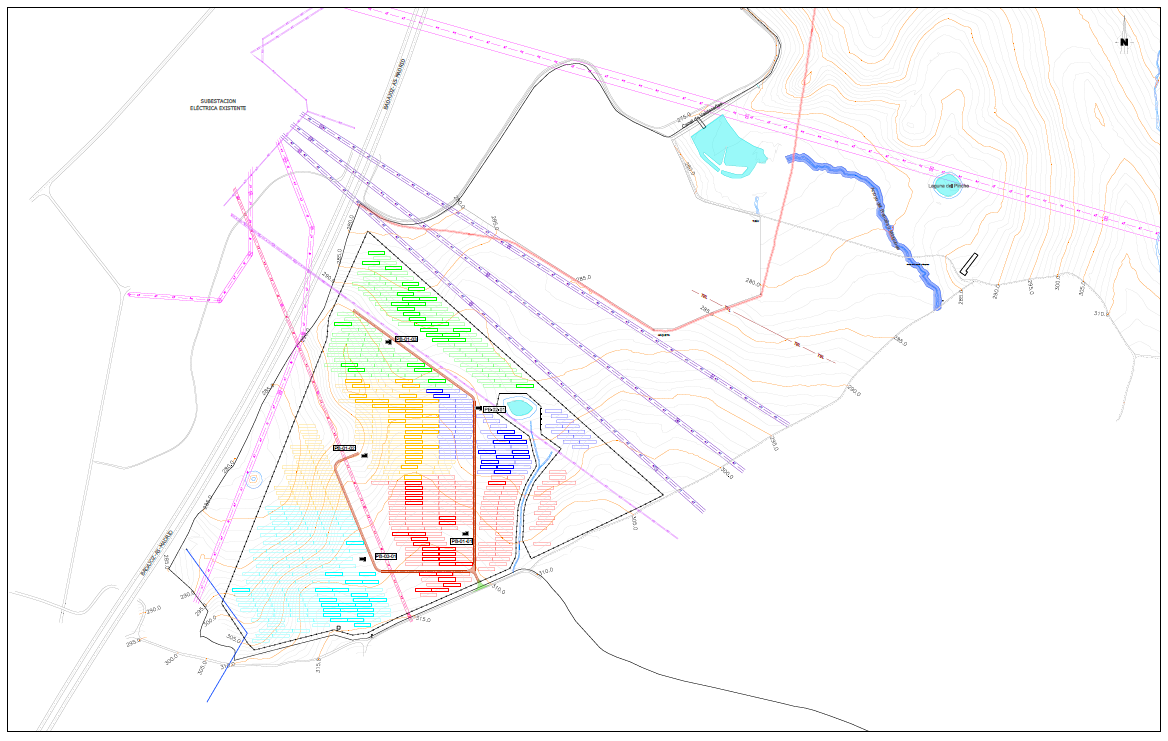

CEMBOX Infra is a BIM-GIS environment enabling the interaction with static and dynamic data and providing: Visualisation, Prediction and Simulations.

CEMBOX Infra Platform

- Management. Coordination and inventory of the information related to a particular project or contract

- Inspection

- Monitoring

- Planning

CEMBOX Infra Advantages

- User Friendly Digital Twin Environment: Management, Inspection and Monitoring.

- Advanced Analytics on Key Assets including pavements, bridges or earthworks, among others.

- Easy Integration and Management of critical infrastructure: better service, reduction of costs and enhanced safety.

CEMBOX, as a level four digital twin according to AUTODESK classification, positions itself as an essential tool for the efficient management of both buildings and transport infrastructures. Its ability to integrate real-time data, advanced simulations, and interactive 3D visualization provides users with unprecedented control over their projects, improving efficiency and reducing operational costs.