As in many other industries, the construction sector is being impacted by digitalization and new technologies. In recent years, the development of digitalization in processes and advanced data analysis have meant companies need to adapt to a new work environment. On the other hand, the COVID-19 crisis has accelerated this process, both in mitigating labour restrictions and advancing new forms of work.

What is digital transformation?

Digital transformation is the integration of digital technology into all areas of a business and requires fundamental changes in the field of technology, culture, operations and value delivery. To make the best use of emerging technologies, companies must reinvent themselves and radically transform all their processes and models. It also involves shedding legacy technology, which can be costly to maintain, and modifying corporate culture in order to support the progress brought about by digital transformation. Companies that are open to change and which adapt to a new more agile model will more likely obtain greater corporate success.

Adapting to customers’ new needs and offering a quality solution is one of the main goals of digital transformation.

Why opt for digital transformation?

As a result of the great technological advances we are experiencing, companies are replacing their traditional interactions with digital experiences. Transformation frequently occurs, not because companies choose to transform, but because if they fail to adapt to the new needs demanded by customers and offer a quality solution, organizations seem destined to failure.

On the other hand, those that are open to the changing environment and adapt to a more agile model are more likely to have greater success. This is because digital transformation basically consists of taking into account all aspects of a company, and figuring out how to update them so they evolve in step with technology.

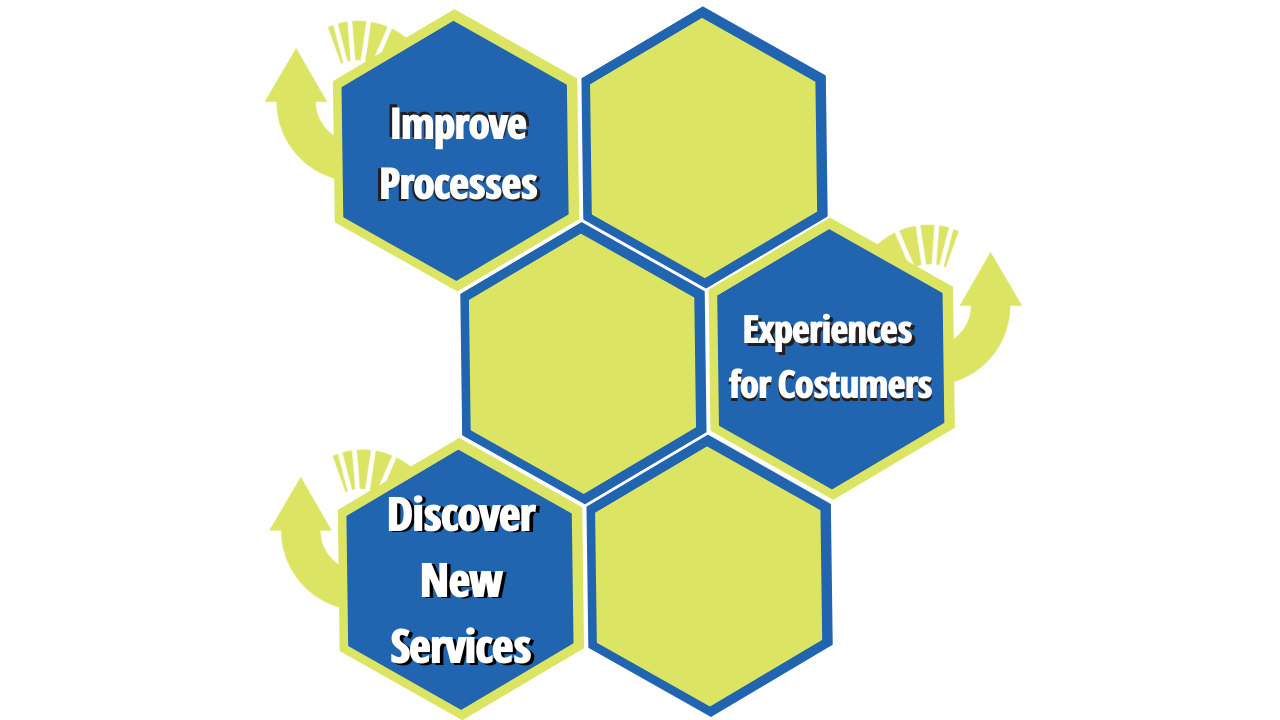

Digitalization offers the following advantages:

- Improve processes: new technology implementation allows for the automation of simpler processes and the elimination of intermediaries in more complex ones. This allows the company to increase its agility and use its human capital more efficiently.

- Discover new services: through emerging technologies, new ways of business can arise. It is important to identify such opportunities and take action.

- Create more personalized and engaging experiences for customers: today’s customers are very demanding and expect companies to listen to them and meet their specific needs. Technology has evolved to adapt to this specific objective.

To make the most of digital data, it is necessary to adopt technologies as they become available, try them out, and use the results obtained to adapt better and look to the future. Although incorporating technology can be very costly, the reward can be much greater.

It is undeniable that companies, employees and consumers have changed the way they act. The customer seeks to be more connected, interact more and trust the brand enhancing loyalty. Therefore, employees and companies change technologically and culturally to adapt to new customer demands.

Digital transformation has to do with the value of services, improving the business model, innovation, differentiation and strengths.

How to develop a digital transformation plan

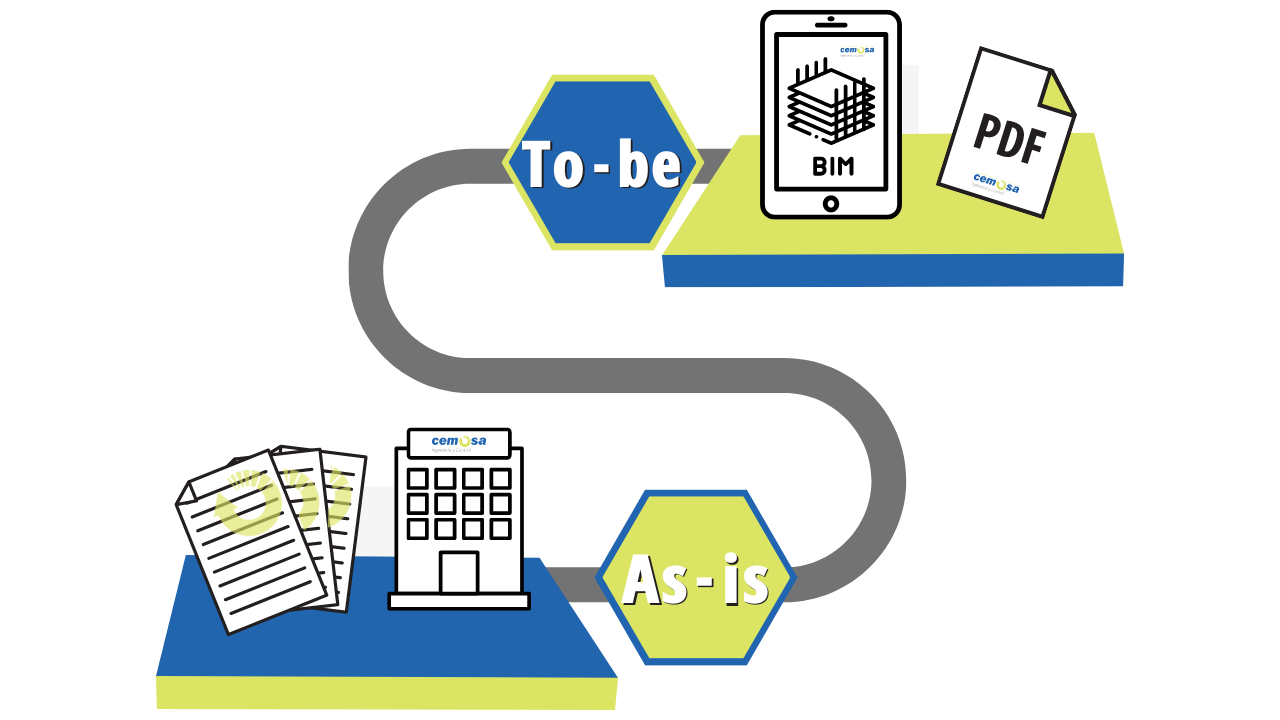

A series of steps must be taken to develop a digital transformation plan to completely transform the company so it can achieve all its objectives.

In the analysis stage, an X-ray is made of the company in order to know the actual status from which an action plan will emerge towards the objective proposed by the digital transformation.

In the action stage, the objectives that will lead to the specific actions to be implemented and monitored are set out. Do not hesitate to seek professional help to ensure the success of your investment.

The industry, therefore, is entering the Fourth Industrial Revolution, so technologies 4.0 such as Data Analysis, Artificial Intelligence (AI), the Internet of Things (IoT) and Digital Twin are the main core in CEMOSA’s digital transformation plan.

CEMOSA’s Digital Transformation

At a strategic level, CEMOSA is positioned in R&D projects such as OMICRON ‘Towards a more automated and optimised maintenance, renewal and upgrade of roads by means of robotised technologies and intelligent decision support tools’ and AICREDITS ‘Artificial Intelligence for Extended Energy Audits’ which are based on using technology to offer new services increasing the user and customer experience, thus consolidating the commitment to the future and in the long term.

At the productive level, CEMOSA has shown determination in its commitment to digitalization by integrating BIM methodology not only in its engineering, but it also develops and uses its own BIM tools in the laboratory for controlling materials and geotechnical characterization.

Consequently, CEMOSA is without any doubt committed to leading this change and being a benchmark in the construction sector, since it has the technology, resources and capabilities to address digital transformation and make it a fundamental competitive advantage in the coming years.