Gallery Info

Description

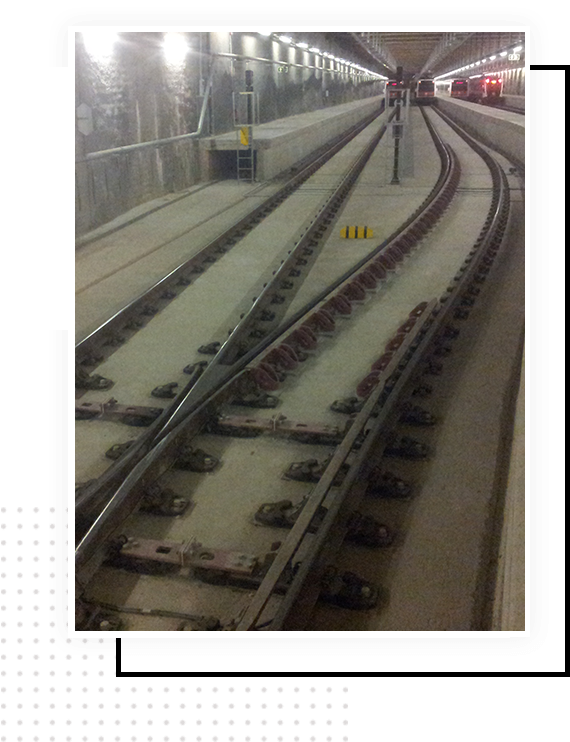

The aim of ROBOTRACK project is the development of a new concept of slab track, economic and environmental sustainable particularly designed to allow an innovative process of execution totally automated through a new robotized system.

From a global view, the project poses innovations in the designing, materials and processes, which allow the system being more competitive than the current slab track systems in the market.

The designing is focusing in the process of execution through a robotized system, automatic and robust, able to install the prefab slab quickly and precisely.

In order to achieve the general objective of the project, the following specific targets are addressed:

- Designing and development of a material for embankment base material for the new slab track, based on RC concrete including environmentally friendly materials, that meet the mechanical properties required with the less cost possible, and with a number of characteristics that ease the execution with robotic elements.

- Designing and development of a base material for the production of prefab slabs for the new slab track, throughout the dosing of ultra-high performance concrete optimized to offer better environmental properties with less economical costs.

- Designing and development of the most relevant and significant structural elements of the slab track, support layers and prefab slabs, throughout the use of innovate numerical models based on FEM and dimensioning structural techniques, with the objective of obtain optimized elements from a structural point of view, vibratory behavior, which allows the automation and robotization of the execution.

- Integrated design of the new superstructure of the slab track, defining the solution in transition zones in which the new system will be installed, and a new optimized methodology made especially for it.

- Designing and integration of an automated, robotic and robust system, able to carry out the installation of the prefab slabs during the process of execution, making a process of construction more efficient, safe, reliable, autonomous, with more quality and with less mistakes.

- Validation of the new slab track system with the construction and performing a number of trials in a real-scale demonstrator under cyclic-loading.

- Development of a specific methodology and database required to carry out the Life cost cycle analysis (LCCA) and reliability analysis (RAMS) in sites where the new system of slab track will be implemented.

The participants in the project are the companies VIAS Y CONSTRUCCIONES S.A., CEMOSA, Ferrocarrils de la Generalitat de Catalunya (FGC), Polytechnic University of Valencia (UPV) and the technological center EURECAT.

CEMOSAs role

CEMOSA addresses the design of the base layer made of RC concrete and sustainable aggregate and carries out the reliability analysis (RAMS) and life cost cycle analysis (LCCA) of the whole system.